High pob tshab kho mob qib Polypropylene PP 5090T

High pob tshab kho mob qib Polypropylene PP 5090T

Khoom parameters

| Kev ua tau zoo ntawm qhov project | Cov xwm txheej xeem | Txoj kev xeem | Cov ntaub ntawv xeem | Cov ntaub ntawv unit |

| Melt flow rate | / | TS EN ISO 1133 | 9 | g/10 min |

| Lub shrinkage | / | FPC Txoj Kev | 1.3-1.7 Nws | % |

| Qhov ntom ntawm | / | TS EN ISO 1183 | 0.9 | g/cm3 |

| Tensile yield zog | / | TS EN ISO 527 | 29 | MPa |

| Elongation ntawm qhov tawg | / | TS EN ISO 527 | 200 | % |

| Rockwell hardness | / | ISO 2039 Daim Ntawv Pov Thawj | 105 | R |

| Mechanical zog ntawm | ||||

| Khoov modulus | / | ISO 178 | 1422 ib | MPa |

| IZOD notch cuam tshuam lub zog | 23 ℃ | ISO 180 | 10 | kg/cm |

| IZOD notch cuam tshuam lub zog | -20 ℃ | ISO 180 | 4.5 | ISO 180 |

| Thermal deformation kub | / | ISO 75 | 130 | ℃ |

| Kev ua haujlwm thermal | ||||

| Veka softening point | / | TS EN ISO 306 | 155 | ℃ |

| Combustibility | Natural ≥ 2 hli | UAS 94 | 94 HB | Chav kawm |

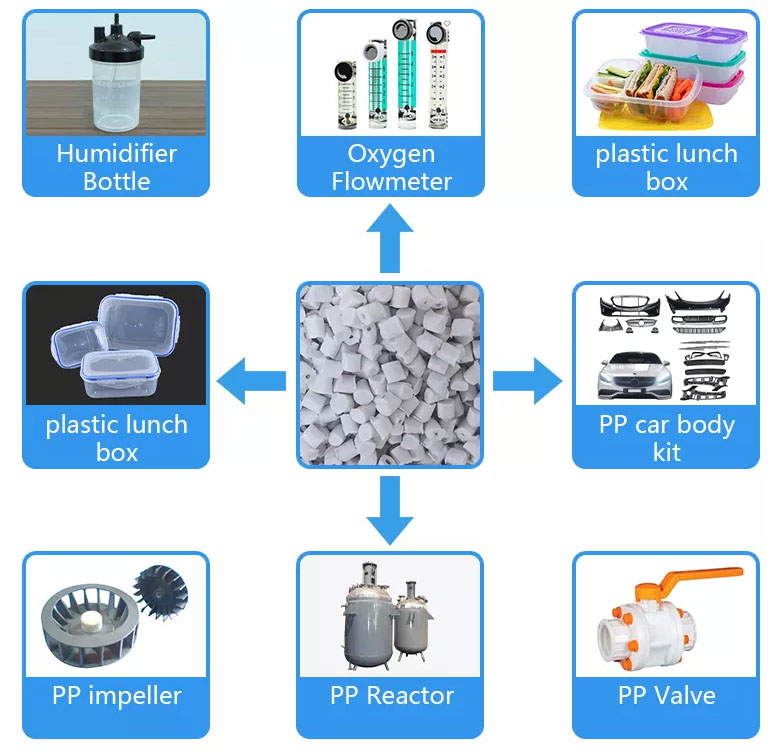

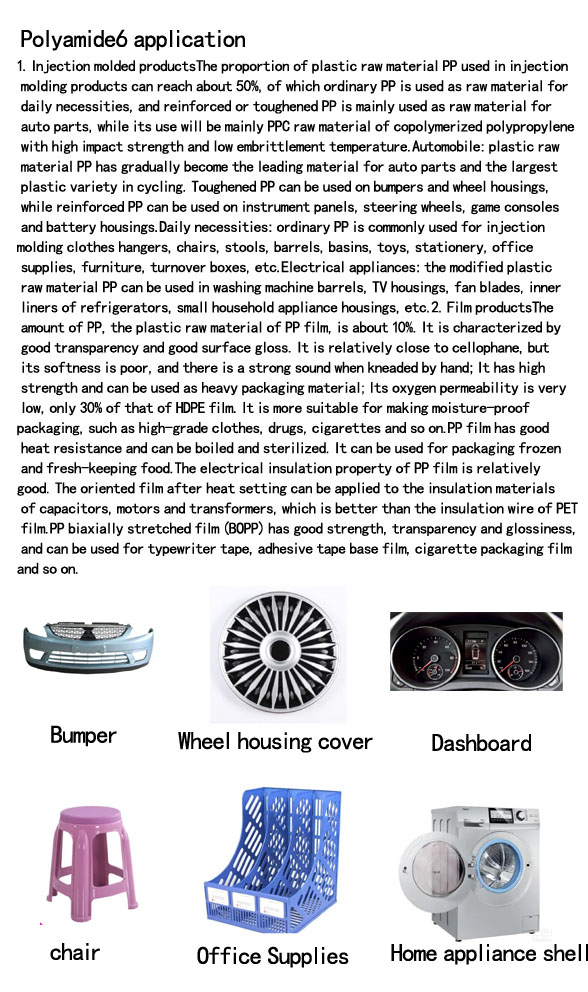

Daim ntawv thov

(ningbo) Taiwan Formosa Plastics pp5090t siv lub ntsiab:

PP yog cov khoom siv semi crystalline.Nws yog ib qho nyuaj tshaj li PE thiab muaj cov ntsiab lus melting ntau dua.Txij li homopolymer hom PP yog nkig heev thaum kub qis dua 0 ℃, ntau cov khoom lag luam PP yog random copolymer nrog 1-4% ethylene lossis clamp hom copolymer nrog cov ntsiab lus ethylene siab dua.Cov khoom siv copolymer hom PP muaj qis dua thermal distortion kub (100 ℃), tsis tshua muaj pob tshab, tsis tshua muaj gloss thiab tsis tshua muaj rigidity, tab sis muaj zog cuam tshuam lub zog.

Tus nqi ntws MFR ntawm PP yog li ntawm 1 txog 40. PP nrog qis MFR muaj kev cuam tshuam zoo dua tab sis qis zog tensile.Rau cov ntaub ntawv nrog tib MFR, lub zog ntawm cov copolymer hom yog siab dua li homopolymer hom.Vim crystallization, qhov shrinkage tus nqi ntawm PP yog siab heev, feem ntau 1.8-2.5%.Thiab cov kev taw qhia sib xws ntawm shrinkage yog zoo dua li ntawm PE-HD thiab lwm yam ntaub ntawv.Ntxiv 30% iav additive tuaj yeem txo qhov shrinkage rau 0.7%.

Homopolymer hom thiab copolymer hom PP cov ntaub ntawv muaj cov dej noo zoo heev nqus, acid-base corrosion kuj thiab dissolution kuj.Txawm li cas los xij, nws tsis muaj qhov ua rau muaj ntxhiab hydrocarbon (xws li benzene) hnyav thiab chlorinated hydrocarbon (carbon tetrachloride) hnyav.PP tsis muaj oxidation tsis kam ntawm qhov kub thiab txias li PE ua.

Raws li kev ua haujlwm saum toj no, PP yog tsim rau cov khoom hauv qab no:

1. Txhaj tshuaj: li qub, khoom siv, cov thawv, tsheb, kaw, cov khoom siv hluav taws xob, lub raj mis dej, cov khoom ntim khoom noj, cov khoom siv hauv tsev, cov khoom ua si, cov koob txhaj tshuaj uas tsis yog ua ntej.

2. Extrusion: daim ntawv tuab, ntawv, yeeb nkab, straw, khi daim kab xev, ntawv sau, BOPP zaj duab xis Sheet thiab sawb.

3. Tshuab molding: lub raj mis.

4. Thermoforming: tais, tais, jelly khob, khob dej.

5. Flat yarn: woven hnab, thawv ntim, ntaub pua plag.