High cuam tshuam retardant qib Polypropylene PP K8003

High cuam tshuam retardant qib Polypropylene PP K8003

yam ntxwv

Zoo UV Resistance Zoo Tshuaj Resistance Impact Hloov.

Kev tiv thaiv siab

| PIB K8003 | ||||

| Cov khoom | Chav tsev | Test Standard | Chav tsev | Yam khoom muaj nqis |

| Specific Gravity | ISO 1183 | 23 ° C | 0.893 ib | |

| Melt Flow Rate | ISO 1133 | 250 ° C, 5 KG | g/10 min | 2.4 |

| Pwm Shrinkage | TS EN ISO 2577 | 23 ° C | % | 1.2 ~ 1.4 hli |

| Mechanical Properties | ||||

| Tensile zog | TS EN ISO 527 | 50 hli / min 23 ° C | Mpa | 22.2 |

| Tensile Elongation ntawm Break | TS EN ISO 527 | 50 hli / min 23 ° C | % | 435.8 ib |

| Flexural zog | ISO 178 | 2 hli / min 23 ° C | Mpa | 22 |

| Flexural Modulus | ISO 178 | 2 hli / min 23 ° C | Mpa | 679 ib |

| Charpy Impact Strength, Notched | ISO 179/1 eA | 23°c kub | KJ/M2 | 5 3.3 |

| Thermal Properties | ||||

| HDT | ISO 75 | 1.82MPa, 3.2 hli | °C | 90-105 : kuv |

| Flammability | UL94 ua | 3.2 hli / 1.5mm | HB | |

Khoom siv

PP lub cev muaj zog: tsis muaj tshuaj lom, tsis muaj ntxhiab, tsis qab, milky dawb, siab crystalline polymer nrog cov txheeb ze molecular hnyav li ntawm 80000-150000.Qhov ceev me me: 0.89-0.91g / cm3, nws yog ib qho ntawm cov khoom siv sib xws hauv cov yas.Muaj zog hydrophobicity: tus nqi nqus dej hauv dej rau 24h tsuas yog 0.01%.Zoo formability.

Cov khoom siv tshuab PP muaj cov crystallinity siab thiab cov qauv tsis tu ncua, yog li nws muaj cov khoom siv zoo heev.Qhov kev ua tau zoo tshaj plaws yog khoov qaug zog ua haujlwm.

PP muaj qhov ua tau zoo thaum tshav kub kub.Cov khoom tuaj yeem ua kom tsis muaj menyuam ntawm qhov kub siab tshaj 100 ° C. nyob rau hauv qhov xwm txheej tsis muaj kev quab yuam sab nraud, nws yuav tsis deform ntawm 150 ° C. Lub embrittlement kub yog - 35 ℃.Qhov nce ntawm isotacticity lossis txo qhov hnyav molecular yog qhov zoo rau kev txhim kho cov khoom thermal.

Chemical stability: tshuaj stability ntawm PP yog zoo heev.Nws tuaj yeem raug eroded los ntawm cov concentrated sulfuric acid thiab concentrated nitric acid, thiab yog qhov ruaj khov rau lwm cov tshuaj reagents;Txawm li cas los xij, qhov hnyav molecular aliphatic hydrocarbons, muaj ntxhiab hydrocarbons thiab chlorinated hydrocarbons tuaj yeem soften thiab o polypropylene, thiab nws cov tshuaj ruaj khov yog txhim kho nrog kev nce ntawm crystallinity.

Raws li kev ua haujlwm saum toj no, PP yog tsim rau cov khoom hauv qab no:

1. Txhaj tshuaj: valve, fittings, crates, tsheb, kaw, khoom siv, kettles, ntim khoom noj, khoom siv hauv tsev, cov khoom ua si, cov koob txhaj tshuaj uas tsis yog prefilled.

2. Extrusion: tuab ntawv, ntawv, yeeb nkab, straw, strapping, ntawv sau, BOPP Zaj duab xis, nyias daim ntawv, band.Tshuab Moulding: fwj.

3. Thermoforming: tais, tais, jelly khob, khob dej.

4. Flat yarn: woven hnab, jumbo hnab, ntaub pua plag.

5. Fiber: multifilament, ntaub pua plag, Spundbond, non-wovens.

6. Zaj duab xis: Cast film (CPP), Blown film (IPP).

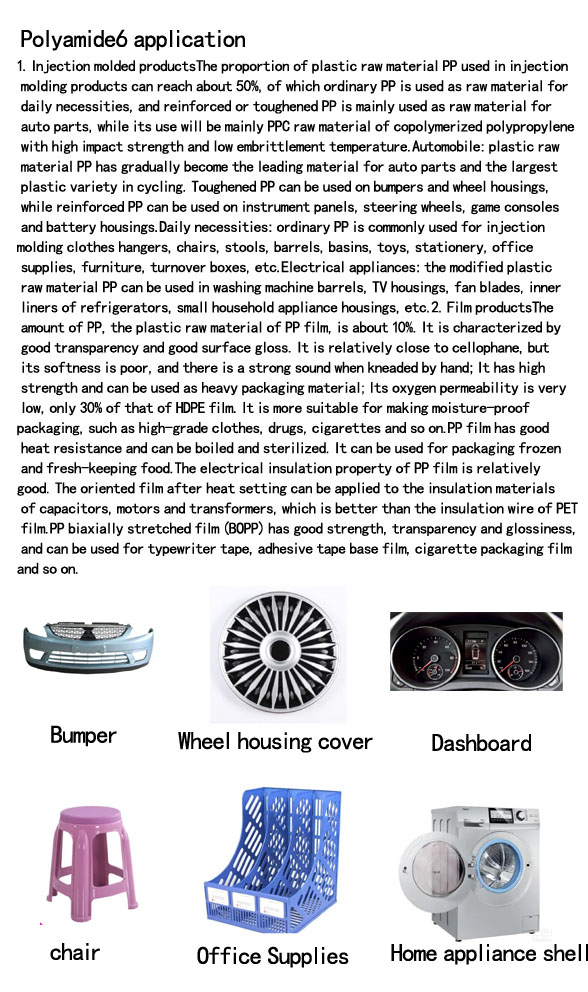

Daim ntawv thov